Though manufacturing is a somewhat bygone industry, it might surprise you to learn how much it has benefited from the use of big data. Manufacturing is evolving, thanks to its access to new analytical tools and better ways to gather information.

How Big Data Is Changing Manufacturing

Below are just a few of the ways big data is reshaping manufacturing in the U.S.:

- Higher accuracy. Successful fabrication depends on sharp accuracy for manufacturers to continue to be competitive. Before big data came along, the best ways to improve were to invest in better equipment such as MIG welders, or invest in better employee training. With big data, though, manufacturers can use computer programs to refine the process, and analyze errors more skillfully so they can be prevented.

- Higher yield. Most manufacturers take in raw materials and to create finished products, which they sell for more than they paid for the intake. In this system, the higher the yield you can get (that is, the fewer raw materials you use per finished product), the more profitable your operation. New big-data applications give manufacturers greater insight into their overall yield, and opportunities to improve their operations to make more money for every batch of product.

- Better forecasting. Supply-chain forecasting and demand forecasting are two critical tools for manufacturers. They can determine how much you need to produce, when to slow down production for the off seasons, and how much to hold in your warehouses or ship out. Big data is helping manufacturers grasp the ebb and flow of this supply chain relationship better, so they produce tactically, when it’s most worthwhile to produce.

- Predicting and tracking supplier performance. Manufacturers can also use big data to track supplier performance. If a supplier consistently ships inferior products that are unusable, for example, you can accurately calculate the likelihood of this, and determine whether it’s cost-effective to select a new supplier.

- Higher traceability. Big data also gives manufacturers more transparency and traceability. How much of your raw materials get lost during production, and at what stage of production? How much did a given batch yield, and where is it currently stored? How long will it take to ship, and once it’s on its way, where is it? Big data helps you track all these phases of production and delivery, and gives you insight into areas of possible inefficiency.

- Advanced custom jobs. Big data is making is it more possible to create advanced custom jobs, by taking data from past efforts and imagining new ways to manipulate raw materials. It can also aid in reverse engineering, to come up with new solutions to familiar problems.

- ROI and operational efficiency. Finally, big data is giving manufacturers more insight into the true efficiencies of their operations, as well as the return on investment (ROI) they accrue in upgrades, such as new equipment or new advertising strategies.

What Does This Mean for Manufacturers?

What can manufacturers do with this information? What are they currently doing to embrace and make good use of these trends?

- Higher profitability. First, manufacturers push for higher profitability. In an area that’s traditionally been limited by factors such as raw material cost and hard limits to production, there are suddenly new avenues to cut costs and get more out of every production run. Business owners are excited to explore these opportunities and earn more revenue.

- More competition. Next, as manufacturers adopt big-data strategies, their competitors feel increased pressure to adopt similar — and even better — approaches. The increased competition forces more and more traditional manufacturers to upgrade their internal systems, and it’s only going to grow more lively in the future.

- Demand for new roles. Even lean-data applications can be challenging to an outsider, or anyone unfamiliar with data analysis. The new technologies are impressive, but they require someone sufficiently knowledgeable to implement and manage them. Thus, manufacturers are driven to hire new positions for their teams and migrate old ones as well.

Despite being an economic area that has undergone comparatively few technological leaps since the Industrial Revolution, manufacturing is feeling the impact of big data. In the coming years, more manufacturers will be encouraged or compelled to adopt new standards for data gathering, storage, and analysis if they want to stay in business.

from SmartData Collective – The World’s Best Thinkers on Data http://www.smartdatacollective.com/larry-alton/500916/7-ways-big-data-changing-manufacturing

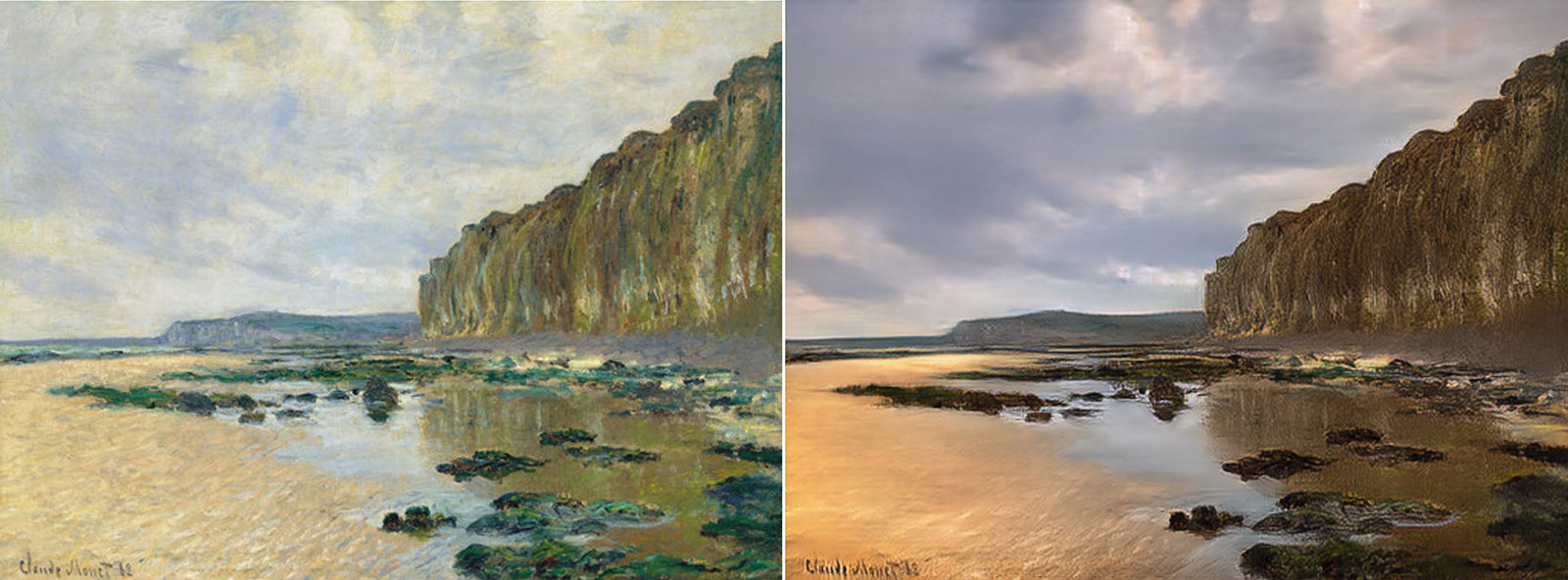

Impressionist art is more about feelings than realism, but have you ever wondered what Monet actually saw when he created pieces like Low Tide at Varengeville (above)? Thanks to researchers from UC Berkeley, you don’t need to go to Normandy and wait…

Impressionist art is more about feelings than realism, but have you ever wondered what Monet actually saw when he created pieces like Low Tide at Varengeville (above)? Thanks to researchers from UC Berkeley, you don’t need to go to Normandy and wait…